AI enables optoelectronic components to laser communication

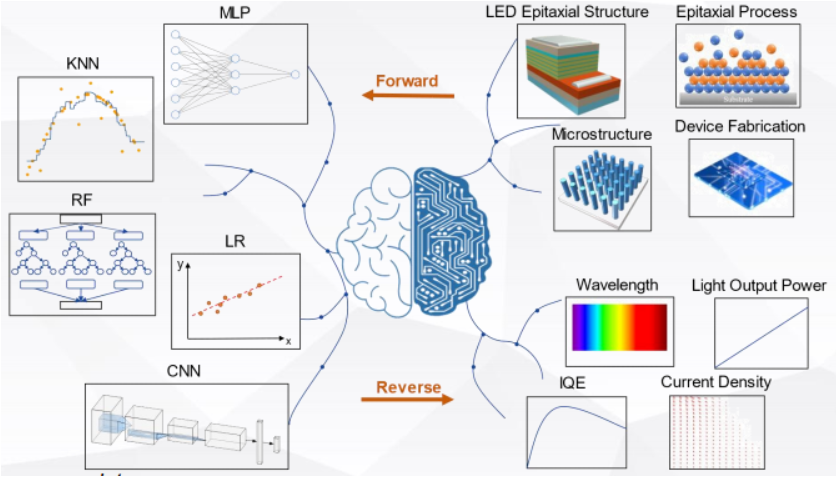

In the field of optoelectronic component manufacturing, artificial intelligence is also widely used, including: structural optimization design of optoelectronic components such as lasers, performance control and related accurate characterization and prediction. For example, the design of optoelectronic components requires a large number of time-consuming simulation operations to find the optimal design parameters, the design cycle is long, the design difficulty is greater, and the use of artificial intelligence algorithms can greatly shorten the simulation time during the device design process, improve the design efficiency and device performance, 2023, Pu et al. proposed a modeling scheme of femtosecond mode-locked fiber lasers using recurrent neural networks. In addition, artificial intelligence technology can also help regulate the performance parameter control of optoelectronic components, optimize the performance of output power, wavelength, pulse shape, beam intensity, phase and polarization through machine learning algorithms, and promote the application of advanced optoelectronic components in the fields of optical micromanipulation, laser micromachining and space optical communication.

Artificial intelligence technology is also applied to the accurate characterization and prediction of the performance of optoelectronic components. By analyzing the working characteristics of components and learning a large amount of data, the performance changes of optoelectronic components can be predicted under different conditions. This technology is of great significance for the application of enabling optoelectronic components. The birefringence characteristics of mode-locked fiber lasers are characterized based on machine learning and sparse representation in numerical simulation. By applying sparse search algorithm to test, the birefringence characteristics of fiber lasers are classified and the system is adjusted.

In the field of laser communication, artificial intelligence technology mainly includes intelligent regulation technology, network management and beam control. In terms of intelligent control technology, the performance of the laser can be optimized through intelligent algorithms, and the laser communication link can be optimized, such as adjusting the output power, wavelength and pulse shape of the laser and selecting the optimal transmission path, which greatly improves the reliability and stability of laser communication. In terms of network management, data transmission efficiency and network stability can be improved through artificial intelligence algorithms, for example, by analyzing network traffic and usage patterns to predict and manage network congestion problems; In addition, artificial intelligence technology can undertake important tasks such as resource allocation, routing, fault detection and recovery to achieve efficient network operation and management, so as to provide more reliable communication services. In terms of beam intelligent control, artificial intelligence technology can also achieve accurate control of the beam, such as assisting in adjusting the direction and shape of the beam in satellite laser communication to adapt to the impact of changes in the curvature of the earth and atmospheric disturbances, to ensure the stability and reliability of communication.

Post time: Jun-18-2024